More Monotony, But More Money

To a large degree, Ford’s implementation of the Five-Dollar Day cannot be appreciated without first understanding his advances with the moving assembly line. Experiments through 1913 and into 1914 reduced the time required to build a Model T automobile from 12½ hours to a mere 93 minutes. Increased efficiencies lowered production costs, which lowered customer prices, which increased demand. The public was eager to buy all of the cars Ford could build.

Explosive production gains came at the cost of worker satisfaction. The very goal of the moving assembly line was to take what had been relatively skilled craftwork and reduce it to simple, rote tasks. Workers who had taken pride in their labor were quickly bored by the more mundane assembly process. Some took to lateness and absenteeism. Many simply quit, and Ford found itself with a crippling labor turnover rate of 370 percent. The assembly line depended on a steady crew of employees to staff it, and training replacements was expensive. Ford reasoned that a bigger paycheck might make the factory’s tedium more tolerable.

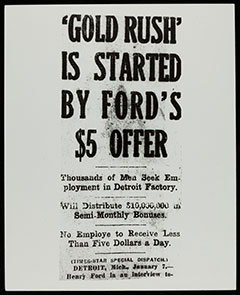

|

| Ford’s Five-Dollar Day prompted banner headlines around the world. THF204872 |

If the need to retain workers was a partial motivation for the Five-Dollar Day, then the solution may have worked too well. Within days of the announcement, thousands of applicants came to Detroit from all over the Midwest and entrenched themselves at Ford’s gate. The company was overwhelmed, riots broke out, and the crowds were turned away with fire hoses in the icy January weather. Ford announced that it would only hire workers who had lived in Detroit for at least six months, and the situation slowly came under control.

Strings Attached

Those who did have jobs at Ford soon discovered that there were even more conditions. Lost in the headlines was the fact that the pay increase was not a raise per se, it was a profit sharing plan. If you made $2.30 a day under the old pay schedule, for example, you still made that wage under the Five-Dollar plan. But if you met all of the company’s requirements, Ford gave you a bonus of $2.70.

Part of Henry Ford’s reasoning behind the Five-Dollar Day was that workers who were troubled by money problems at home would be distracted on the job. If higher pay was intended to eliminate these problems, then Ford would make sure that his employees were using his largesse “properly.” The company established a Sociological Department to monitor its employees’ habits beyond the workplace.

To qualify for the pay increase, workers had to abstain from alcohol, not physically abuse their families, not take in boarders, keep their homes clean, and contribute regularly to a savings account. Moral righteousness and prudent saving were all well and good, but they were not generally an employer’s business—at least not outside of working hours. In contrast, Ford Motor Company inspectors came to workers’ homes, asked probing questions, and observed general living conditions. If “violations” were discovered, the inspectors offered advice and pointed the families to resources offered through the company. Not until these problems were corrected did the employee receive his full bonus.

Modifying manufacturing methods was one thing. Modifying the people who carried out those methods was quite another. Henry Ford and his supporters may well have seen the Sociological Department as a benevolent tool to benefit his employees, but the workers came to resent the intrusion into their personal lives. Ford himself eventually realized that the Sociological Department was unsustainable. By 1921, it was largely dissolved.

Wages Up, Sales Up

As for charges that Ford raised pay in pursuit of publicity, there’s no question that the Five-Dollar Day brought a spotlight on Ford Motor Company. But publicity is fleeting, and the Five-Dollar Day’s impact was far greater than newspaper headlines. Other automakers soon boosted their own wages to keep pace with Ford. Automobile parts suppliers followed suit. In time, workers in any number of fields were earning genuine “living wages” that afforded them comfort and security above basic food, shelter and clothing needs.

It’s no small detail that, as Henry Ford slyly observed, in the course of improving his employees’ standard of living, Ford also created a new pool of customers for his Model T. The Five-Dollar Day helped to bring members of America’s working class into its middle class. Better wages, combined with the affordable goods produced by the assembly line, are cornerstones of the prosperity that has characterized American life for so many of the past 100 years.

| |

-- Matt Anderson, Curator of Transportation |

|