How We Manage Vehicle Safety

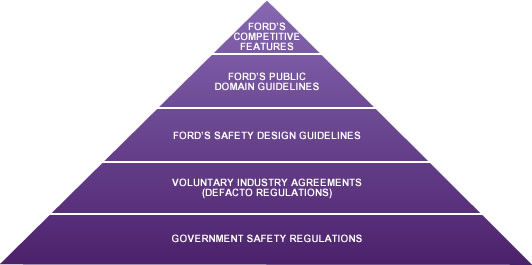

Here at Ford, our objective is to design and manufacture vehicles that achieve high levels of vehicle safety for a wide range of people over the broad spectrum of real-world conditions. Real-world safety data, driver behavior, research, regulatory requirements and voluntary agreements provide much of the input into our safety processes, including our Safety Design Guidelines (SDGs) and Public Domain Guidelines (PDGs). (See graphic below.) The SDGs are Ford’s stringent internal engineering design targets that exceed regulatory requirements and define many additional requirements that are not regulated. The PDGs are Ford guidelines that focus specifically on helping to ensure that our vehicles earn top marks in relevant public domain assessments.

Our PDGs have been revised over the past few years to take into account significant changes in public vehicle testing programs. Globally, the public domain tests have become significantly more stringent. In the U.S., for example, the New Car Assessment Program (NCAP), run by the National Highway Traffic Safety Administration (NHTSA), has added a “rigid pole impact test” to assess side-impact safety (in addition to an existing side-impact test); implemented the use of a smaller dummy in the passenger seat in frontal impact tests; and made significant changes to the injury criteria. In addition, NHTSA will now provide an overall vehicle score (a “star” rating, from one to five stars) representing a combination of the vehicle’s front, side and rollover ratings. To earn a Top Safety Pick from the Insurance Institute for Highway Safety (IIHS), a vehicle must now receive a “good” rating for a new roof strength test, in addition to “good” ratings in front, side and head restraint assessments. EuroNCAP has added a test for whiplash neck injury protection in rear impact, and also now rewards speed limiters and the inclusion of electronic stability control technologies as a standard feature. Like NHTSA, EuroNCAP also now gives each vehicle an overall star rating representing a combination of individual ratings. (EuroNCAP made this change in 2009.)

Internally, Ford utilizes engineering analyses, extensive computer modeling and crash and sled testing to evaluate the performance of vehicles and individual components. These rigorous evaluations help to confirm that our vehicles meet or exceed regulatory requirements and our even more stringent internal guidelines. Our state-of-the-art crash-test facilities include the Safety Innovation Laboratory in Dearborn, Michigan, and the extensive crash-test facilities in Merkenich, Germany, and Dunton, England.

Global Technical Regulations

The automotive industry is highly regulated, and two systems of vehicle regulation predominate globally: the United Nations Economic Commission for Europe Regulations and the U.S. Federal Motor Vehicle Safety Standards. To meet the relevant regulations of each market in which it sells, a manufacturer must modify its vehicle designs and features. This is a particular challenge for Ford, given our increased focus on producing vehicles with the same platforms globally. It can increase vehicle complexity and cost, often without demonstrated, incremental real-world safety benefit.

With the aim of harmonizing world vehicle regulations, 31 countries are working together to develop Global Technical Regulations (GTRs). Ford actively participates in the GTR development process.

Thus far, 11 GTRs have been developed (though not all relate to motor vehicle types relevant to Ford). Progress has been slow due to the difficulty of reconciling varied national requirements and the historical differences of existing regulations. Despite these challenges, Ford continues to believe that true harmonization has the potential to significantly reduce complexity while maintaining high levels of vehicle safety, security and environmental performance, and we plan to continue supporting global harmonization efforts.

Haddon Safety Matrix

Vehicle safety is the product of complex interactions among the driver, the vehicle and the driving environment. We use the Haddon Safety Matrix (developed by William Haddon, a former NHTSA administrator and IIHS president) to take a holistic view of the factors that affect vehicle safety.

The Haddon Matrix looks at injuries in terms of causal and contributing factors, including human behavior, vehicle safety and the driving environment. Each factor is then considered in the pre-crash, crash and post-crash phases. In the pre-crash phase, the focus is to help avoid the crash. In the crash and post-crash phases, the primary objective is to help reduce the risk of injury to occupants during and after a collision. Another goal is to minimize the amount of time that elapses between the crash and when help arrives.

Human Behavior |

Vehicle Safety |

Environment |

|

|---|---|---|---|

Pre-Crash(accident avoidance) |

|

|

|

Crash(occupant protection) |

|

|

|

Post-Crash(injury mitigation) |

|

|

|

Examples of Ford Actions |

|

|

|

- Overview

- Economy Data

- Environment Data

- Society Data