Sustainable Materials

Materials are an important element of a vehicle’s lifecycle sustainability. Choices about materials can influence the safety, fuel economy and performance of the vehicle itself and can have implications throughout the value chain. A material can be more or less sustainable based on a number of factors, including its origin (virgin, renewable or recycled), the resources and manufacturing methods used, the emissions produced throughout its lifecycle, and its application.

Ford has been working for many years to increase the use of recycled and renewable materials and reduce the use of undesirable materials. Vehicles in North America typically are composed of 20 to 25 percent post-consumer recycled material by weight, primarily due to the extensive use of metals with recycled content. Therefore, Ford has concentrated its efforts on developing new uses for recycled materials in the non-metallic portions of the vehicle, which are typically composed of virgin materials. While the amount of recycled content in each vehicle varies, we are continuously increasing the amount of recycled material used in each vehicle line. As described in the section on Design for Lifecycle Sustainability, we have tools available such as Design for Sustainability, lifecycle assessment and lifecycle costing which help us to make beneficial materials choices on future products.

For many years, Ford has had a Voluntary Recycled Content Usage Policy in North America, which sets goals for the use of non-metallic recycled content for each vehicle and increases those targets year by year and model by model. Under this program, recycled materials are selected for all of our vehicles whenever technically and economically feasible. We are now in the process of reinforcing the targets and migrating successful applications of recycled and renewable content across more vehicles for increased environmental benefit. We are focusing on implementing materials technologies that improve environmental and social performance and lower costs.

To facilitate this, we are working with our commodity business planners, materials purchasers and materials engineers to develop a comprehensive list of cost-effective sustainable materials that can be implemented across multiple parts and vehicle lines. All recycled and renewable materials on this list are evaluated versus comparable virgin grades, to guarantee appropriate mechanical properties and the same level of component performance that would be obtained with virgin materials. By combining sustainable materials goals for updated or redesigned vehicles with sustainable materials identification and testing processes, we are standardizing and broadening the use of sustainable materials in our vehicles.

As part of our sustainable materials strategy we are also developing global materials specifications, which will facilitate the incorporation of sustainable materials where they meet performance requirements. By developing global specifications we will ensure that the benefits of more sustainable materials will have a global impact. For example, we are introducing recycled material specifications onto the same documents that house our virgin material specifications. This will simplify monitoring of the use of recycled content in our vehicles and will ensure that component engineers and Tier 1 suppliers are confident in the performance of the recycled material, by means of a direct comparison with an equivalent virgin material.

Our efforts to use recycled materials where they make financial sense are already bearing fruit. For example, many commodity purchasing plans already list recycled-content materials as a preferred material option, including those for battery trays, battery shields and wheel arch liners. In addition, we developed a comprehensive resin strategy that requires the use of recycled plastics for underbody and aerodynamic shields, fender liners, splash shields, stone pecking cuffs and radiator air deflector shields manufactured in North America.

In addition, Ford has a material specification that defines post-consumer, post-industrial and depolymerized recycled content and ensures that the use of in-house scrap is not counted toward recycling targets. We also have a material specification for recycled content textiles and are working on specifications for renewable materials. These specifications make it easier for vehicle engineers to choose sustainable material options.

As we introduce sustainable materials, we are conscious that recycled materials are not always the preferable solution. For example, we take into consideration whether recycled materials may increase weight or have significant energy demand in collection/recycling. We also consider the availability of a local recycled material feedstock versus the need for a global commonality of materials. Our global materials strategy has dramatically reduced the number of materials we specify and use, to enable quality and cost reductions. (For more information please see Increasing Global Integration.) In some cases, the introduction of recycled and renewable materials will run counter to that commonization progress, since the feedstocks for these materials can vary by region. Therefore, we are focusing on the most-efficient opportunities to use recycled and renewable materials. For example, it is often more efficient to use local waste materials that divert waste from local landfills, than to ship waste material inputs across the globe. We are working to ensure that we use local materials as a feedstock for our recycled content materials.

As a result of this comprehensive sustainable materials strategy, we will increase the sustainable materials content of every new model year vehicle and standardize the use of sustainable materials across more vehicle components.

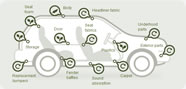

Choosing More Sustainable Materials

Explore the sustainable materials we use in our vehicles.

Related Links

- Overview

- Economy Data

- Environment Data

- Society Data