How We Manage Vehicle Safety

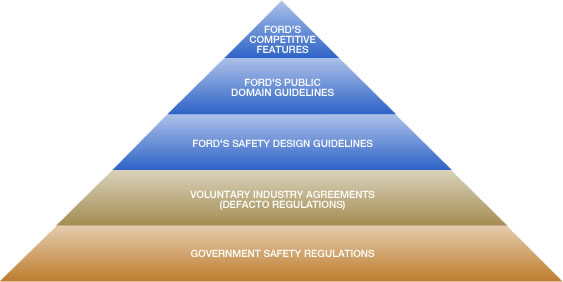

Here at Ford, our objective is to design and manufacture vehicles that achieve high levels of vehicle safety for a wide range of people over the broad spectrum of real-world conditions. Real-world safety data, research, regulatory requirements and voluntary agreements provide much of the input into our safety processes, including our Safety Design Guidelines (SDGs) and Public Domain Guidelines (PDGs). (See graphic below.) The SDGs are Ford's stringent internal engineering design targets that exceed regulatory requirements and define many additional requirements that are not regulated. The PDGs are Ford guidelines that focus specifically on helping to ensure that our vehicles earn top marks in relevant public domain assessments.

Both SDGs and PDGs are managed on a global basis and address the local needs of individual regions and markets. Awareness of road safety is rapidly increasing in many emerging markets, most notably in China, where vehicle safety performance is quickly catching up to that of mature markets. In 2008, Ford created new China-specific SDGs and PDGs to address this issue – raising the bar for vehicle performance in this emerging market beyond regulatory requirements.

Government-run New Car Assessment Programs are becoming an increasingly important tool to improve consumer awareness in emerging markets such as China, but their relevance in developed markets is still also very strong. This is likely to remain the case between 2009 and 2012 as both the National Highway Traffic Safety Administration NCAP and EuroNCAP ratings systems are being significantly altered. As such, fewer vehicles (of all makes) will receive top ratings. Ford is working hard to meet this challenge. We have taken active roles working with NHTSA and EuroNCAP to help ensure the respective rating schemes will be appropriate and will deliver additional real-world benefit. Ford is continuing to work with NHTSA to address several remaining concerns about the new NCAP test requirements before they are implemented.

Ford utilizes engineering analyses, extensive computer modeling and crash and sled testing to evaluate the performance of vehicles and individual components. These rigorous evaluations help to confirm that our vehicles meet or exceed regulatory requirements and our even more stringent internal guidelines. Our state-of-the-art crash-test facilities include the Safety Innovation Laboratory in Dearborn, Michigan, the Volvo Car Safety Centre in Gothenburg, Sweden, and the extensive crash-test facilities in Merkenich, Germany, and Dunton, England.

Global Technical Regulations

The automotive industry is highly regulated, and two systems of vehicle regulation currently predominate globally: the United Nations Economic Commission for Europe (UNECE) Regulations and the U.S. Federal Motor Vehicle Safety Standards. A limited number of countries (including Canada and Mexico) base many of their regulations on U.S. requirements, but the members of the European Union (EU) and much of the rest of the world are increasingly adopting the UNECE regulations or regulations based upon them.

When countries or regions have different regulatory requirements or add unique additional requirements to standard U.S. or UNECE regulations – purportedly to meet the same overall safety objectives – manufacturers must modify their vehicle designs and features to meet the different regulations of the various markets. This increases vehicle complexity and cost, usually with no additional real-world safety benefit.

With the aim of harmonizing world vehicle regulations, the so-called "1998 Agreement" was established.1 The 1998 Agreement has the backing of all the world's major vehicle-producing countries. At present there are 31 contracting parties to the Agreement, including the United States, Japan, Canada, Russia, South Korea, South Africa, India, the EU and a number of individual EU member states. As a result of the 1998 Agreement, which is administered by UNECE Working Party 29, the signatory countries have begun to work together to develop harmonized Global Technical Regulations (GTRs).

Ford Motor Company participates in the GTR development process. The first GTR was published in 2004, and since then eight more have been developed. GTRs for head restraints, safety glazing, electronic stability control systems and pedestrian protection were completed in 2008.

Progress toward true harmonization (i.e., complete alignment of regulations within a GTR) has been challenging, due to the difficulty of reconciling varied national requirements and the historical differences of existing regulations. Despite these challenges, Ford continues to believe that harmonization has the potential to significantly reduce global complexity while maintaining high levels of vehicle safety, security and environmental performance, and we will continue to support the harmonization of global regulations via the 1998 Agreement.