Enhancing People’s Lives

Learn how we are changing lives for the better

We have a role to play in protecting the planet by reducing the emissions from our vehicles, operating world-class facilities and helping our suppliers reduce their impact on the world around us.

Climate change is one of the most pressing global challenges of our time, as well as one of our salient human rights issues (pdf, 2.8MB), so helping address it is a strategic priority for Ford. We have a responsibility to reduce the CO2 emissions associated with the use of our vehicles, as well as from our operations and supply chain.

We support CO2 reductions consistent with the Paris Climate Accord

We will use 100 percent renewable energy for all manufacturing plants globally by 2035

We aspire to achieve zero air emissions from our facilities

Stabilizing CO2 levels in the atmosphere is extremely challenging and requires everyone around the world to do their part. To help keep the rise in global temperature below 2°C, in line with the Paris Climate Accord, we’re streamlining our portfolio, improving fuel efficiency and lowering the lifetime emissions associated with vehicle use. We are also working to reduce the emissions, energy use and water consumption associated with our operations and throughout our supply chain, and transitioning to 100 percent renewable energy sources.

See how we’re reducing our carbon footprint

As we pursue the opportunities of a changing world, our long-term roadmap guides our migration toward new engine, transmission and powertrain technologies, and lower-carbon fuels. As well as improving the efficiency of hybrid and conventional internal combustion engine vehicles, we also plan to introduce hybrid and fully electric vehicle models around the world by 2022.

At our production sites, we’re rethinking how we use energy to help cut emissions. We’ve already achieved our 2025 manufacturing emissions goal to reduce the carbon footprint of our operations eight years early, so we have now set a new target: an 18 percent reduction by 2023. This is in addition to our goal of using 100 percent renewable energy for manufacturing plants globally by 2035.

In support of our new ambition to use 100 percent renewable energy for all our manufacturing plants globally by 2035, we announced our largest-ever renewable energy procurement in February 2019. The 500,000 MWh of wind power, locally sourced through DTE Energy, will meet the needs of our Dearborn Truck Plant, the Michigan Assembly Plant and several other facilities in southeast Michigan.

In 2019, we published our first Climate Change Scenario Report (pdf, 3.63MB), in accordance with the Task Force on Climate-related Financial Disclosure (TCFD) expectations. It details our vision for the transition to a low-carbon economy and assesses the resilience of our strategies for managing climate risk in the future. In addition, we are now reporting on SASB standards (pdf, 173KB) and have produced our first TCFD Index (pdf, 173KB).

Large manufacturers such as Ford are reducing their environmental impact by using water responsibly and reducing waste, and magnifying their efforts by replicating best practice throughout their supply chains.

We will achieve true zero waste to landfill across our operations

We will eliminate single-use plastics from our operations by 2030

We will make zero water withdrawals for manufacturing processes

We aspire to use freshwater for human consumption only

Access to safe, clean water and adequate, accessible sanitation is one of our salient human rights issues (pdf, 2.8MB). Water is also critical to our operations and, as a signatory to the UN Global Compact CEO Water Mandate, we appreciate the need to use it efficiently and sustainably. The automotive industry is also resource intensive, so we work hard to make our facilities more efficient, create less waste, and reuse or recycle any waste we do generate wherever we can.

Find out how we’re trying to do more with less

Many global water challenges have a local context, so we tailor our approach accordingly, especially in water-stressed countries. We have set goals to achieve zero water withdrawals in our manufacturing processes and to only use freshwater in our operations for human consumption. We hope to achieve these ambitions by switching to technologies that don’t require water and by using other companies’ wastewater where we can.

Taking a step toward our ambitions, our Chicago Assembly Plant has saved 23 million gallons of freshwater in just four months by using digital technology from Nalco Water to track water data and identify real-time solutions to avoid water loss.

Our global waste reduction plan outlines how the better use of resources, more recycling and working to eliminate single-use plastics will help us achieve true zero waste to landfill wherever it’s feasible. We have halved facility waste to landfill since 2014, and now have 88 sites that don’t send any waste to landfill.

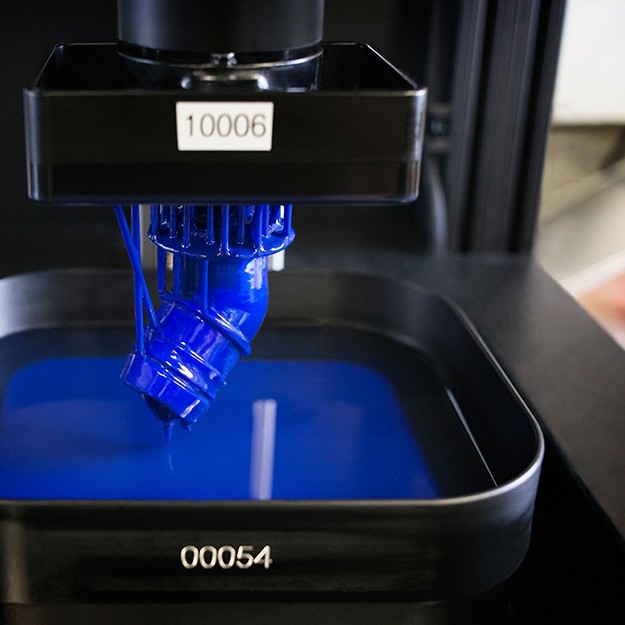

We’re always looking for new ways to make our operations more efficient, and we’re exploring the potential of the latest technology at our Advanced Manufacturing Center in Redford, Michigan. Around 100 experts at our new development hub are 3D-printing auto parts from sand, nylon powder and carbon, enabling cross-continental working through augmented and virtual reality, and seeing how collaborative robots (“cobots”) can help assembly line workers perform repetitive or strenuous tasks.

We can’t tackle complex issues such as resource use and waste management by ourselves, but we can work with others in our supply chain to reduce our combined impact. That’s where our Partnership for a Cleaner Environment (PACE) program comes in, enabling us to identify and share best practice with 50 of the key players in our supply chain.

Eight participating Ford suppliers report that they expect to save an estimated 480 million gallons of water from 2018 to 2030 – enough to fill 730 Olympic-sized swimming pools.

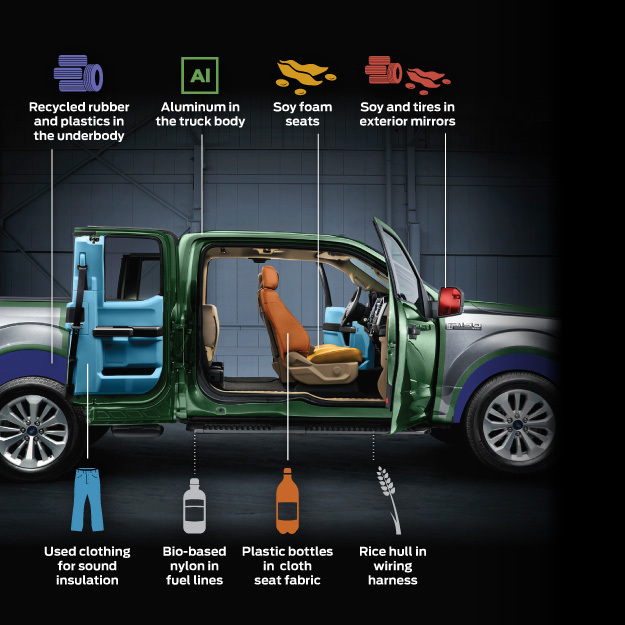

With a vehicle typically containing hundreds of different metals, plastics, fabrics and composites, manufacturers are increasingly looking to use renewable and recycled materials that have a reduced life-cycle impact, as long as they provide equivalent or superior performance.

We aspire to only use recycled and renewable plastics in our vehicles globally

We have always explored the applications of renewable and recycled materials in our vehicles. And with the finite nature of fossil fuel-based materials, along with evolving consumer expectations, that work continues to this day. We’re finding ways to use more sustainable materials, which contain less carbon and ease the pressure on natural resources, in our vehicles.

See how we’re using more sustainable materials

Much of the progress we’ve made to date has been achieved by using recycled materials. We currently incorporate post-consumer rubber, nylon carpeting, cotton scraps, shredded banknotes and plastic containers in our vehicles, while the aluminum scrap from our stamping plants is collected and reused through closed-loop recycling processes.

Our scientists have been trying to replace petroleum-based plastics with bio-based materials and agricultural by-products since the turn of the century. We were the first automaker to use soybean-based foam and, over the years, we have also developed foams, plastics and composites derived from wheat, rice, castor, hibiscus, tree cellulose, jute and coconut.

And we’re not stopping there: we’re currently exploring applications for tomato skin, bamboo, agave fiber, dandelion roots and algae too, and working with several corporate and academic partners to find applications for captured CO2. In an industry first that received an Environmental Innovation Award from the Society of Plastics Engineers (SPE), we have also introduced a cellulose hybrid material in the console of the Lincoln Continental.

To ensure our vehicles are treated responsibly at the end of their useful lives, our dealerships reprocess and reuse some of the parts removed during servicing, such as headlamps and windscreen wiper motors. In several markets, Ford owners also have access to take-back networks, where items including tires and batteries are recycled and reused.

Through our work in advancing our planet, we are contributing to the following UN SDGs: