What’s on this page

Acting on Climate

Climate change is a global challenge that affects us all and its societal implications are profound. Climate change, air emissions and air quality are all salient human rights issues (PDF, 1 MB) and a strategic priority for Ford. As well as reducing the impacts associated with our operations and the use of our vehicles, we’re calling for widespread collaboration across industries, communities and borders.

Our Aspirational Goals

We aspire to achieve carbon neutrality by 2050.

We aspire to achieve zero air emissions from our facilities.

We will use 100 percent locally sourced renewable energy for all manufacturing plants globally by 2035.

Driving Change on a Global Scale

Stabilizing atmospheric CO2 concentrations requires major collaboration from a wide range of global stakeholders. Addressing climate change impact is a salient human rights issue and a strategic priority for Ford. We aspire to achieve carbon neutrality by 2050, and are focused on three areas – vehicle use, our factories and our suppliers – which account for about 95 percent of our carbon emissions.

We continue to work with a variety of industries, stakeholders and elected officials to shape policy actions that address climate change, protect the environment and promote technology innovation. Ford is the only full line U.S. automaker committed to doing its part to reduce CO2 emissions in line with the Paris Climate Agreement and working with California for stronger vehicle greenhouse gas standards. We have also joined the CEO Climate Dialogue and the Climate Leadership Council, and signed up to the New Deal for Europe initiative to devise a comprehensive Sustainable Europe 2030 strategy.

Reducing vehicle carbon emissions is similarly challenging. Over the past decade, consumer preference has shifted away from cars, toward trucks and SUVs, as fuel prices have remained low. We have demonstrated our commitment to doing the right thing by pursuing a voluntary agreement with California committing to more stringent vehicle emission reductions.

For the foreseeable future, internal combustion engine vehicles will continue to play a role in most markets. Nonetheless, in line with our beliefs and our strategy, we continue to improve fuel economy and add electric and other low-emission options to our portfolio as technologies and infrastructure develop.

We’re committed to advancing technologies to mitigate our CO2 footprint and creating a positive impact in society. Ford works closely with regulators and technology experts to find ways to reduce emissions from our vehicles, improving air quality while meeting consumers’ expectations.”

Cynthia Williams Global Director, Sustainability, Homologation and Compliance

Communication and Transparency

In an effort to increase transparency about the resiliency of our climate change strategies, we’ve published our second Climate Change Scenario Report. This is in response to the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD), to which we are now formally committed.

Alternative Fuels and Powertrains

Our plan to develop sustainable technologies includes researching and developing alternative powertrains and fuel options across all our vehicles, giving customers more choice. In particular, we are launching electrified versions of all our most popular nameplates, including the all-electric Mustang Mach-E.

Fuel Economy

In 2019, sales data showed 68% of our U.S. customer base preferred a truck to a car. Though fleet-based averages show modest improvements to annual fuel efficiency, several individual nameplates have experienced significant improvements in fuel consumption. From 2012 to 2019, fuel economy for the Ford F-150 improved by 16 percent, the Ford Escape by 14 percent and the Ford Expedition by 30 percent in the same time frame.

We will continue to enhance the fuel efficiency of our light- and medium-duty truck lines by offering full battery and hybrid electric versions of our flagship products.

U.S. Customer Preference

| 2017 | 2018 | 2019 | |

|---|---|---|---|

| Truck | 54% | 66% | 68% |

| Car | 46% | 34% | 32% |

Ford Car and Truck Fuel Economy (mpg)1

| 2017 | 2018 | 2019 | |

|---|---|---|---|

| Combined car and truck fleet average | 29.6 | 28.9 | 29.0 |

| Cars (domestic and import) | 35.2 | 35.7 | 35.6 |

| Truck | 26.1 | 26.3 | 26.8 |

Calculated using the CAFE drive cycle standards. Does not include A/C or Off-Cycle credits. Includes 0.2 mpg FFV credit.

Clean Energy Transition

We’re continuing to improve the way we use energy at our manufacturing facilities and other sites, to help address climate change. As well as using energy more efficiently, we are reducing the GHG emissions from our operations and making our transport more fuel efficient.

At our production sites around the world, we’ve invested in state-of-the-art facilities and the latest production techniques to meet our energy reduction target. Our long-term ambition is to use 100 percent locally sourced renewable energy for all manufacturing plants globally by 2035, without the use of credits.

New Central Energy Plant

Our new state-of-the-art Central Energy Plant, located on the Research and Engineering campus in Dearborn, Michigan, will use significantly less energy and dramatically reduce the company’s carbon footprint. The plant will use 10 times less natural gas than a traditional boiler facility by producing steam as a by-product. Advanced chiller technology will also contribute to a 35 percent reduction in energy use, while an insulated thermal energy tank will reduce the facility’s peak electricity use by 250 percent.

Making the Switch to Renewable Energy

Our Michigan Assembly Plant and Dearborn Truck Plant, as well as several new buildings on our Research and Engineering and Corktown campuses, will be powered by 100 percent renewable energy by January 2021, using locally sourced wind energy through DTE Energy’s MIGreenPower program.

Making a Positive Impact

By improving the operations under our direct control, and encouraging best practices among our suppliers, we hope to make a positive contribution to the world around us through a holistic, science-based approach.

Building on our past achievements and seeking to limit future risks, we are focusing on responsible water stewardship, achieving true zero waste to landfill across our operations, wherever practicable, and phasing out single-use plastics from our operations.

Our Aspirational Goals

We will make zero water withdrawals for manufacturing processes.

We will use freshwater for human consumption only.

We will achieve true zero waste to landfill across our operations.

We will eliminate single-use plastics from our operations by 2030.

Reducing Water Use

Water is vital to many aspects of our operations. Access to safe, clean water and adequate, accessible sanitation is a salient human rights issue (PDF, 1.1 MB). We have a responsibility to use and manage water sources efficiently and sustainably, especially in water-stressed communities such as India, South Africa and Mexico.

Depending on location, we use a variety of water sources in our operations. But in the long term, we are committed to phasing out the use of freshwater in our manufacturing operations. We will achieve this by installing more non-water-based technologies and relying more on alternative sources such as other companies’ treated wastewater.

Leading on Climate and Water

Ford is one of 181 companies on the CDP Climate Change “A List” and has retained its place on the CDP Water Security “A List” for the fifth consecutive year.

One of the ways that Ford shows it is a company that cares about its environmental impact is through the value we place on reducing freshwater utilized in our operations. We have achieved significant water reductions in the past, and we continue to focus on implementing sustainable practices that will benefit our communities.”

Tamberlyn Shell Environmental Compliance Engineer, Environmental Quality Office

Water Reuse and Recycling

At our Irapuato Transmission Plant in Mexico, both internally treated and externally sourced non-potable water is used. In China, treated wastewater recycling systems have been installed at four assembly plants. And in the United States, the Flat Rock Assembly Plant and Kansas City Assembly Plant have recycling and reuse systems to generate treated wastewater to supplement water use in paint shops.

Improving waste segregation is essential for us to meet our sustainability goals. At Ford manufacturing plants, through programs such as waste management visual aids and on-site waste recycling audits, we are proud of what we do every day to reduce our environmental footprint.”

Xiaoxiao Yu Plant Environmental Control Engineer, Essex Engine Plant, Canada

Going for Zero

Operating in a resource-intensive industry, we are focused on optimizing efficiency and creating less waste. We reuse or recycle any waste we do generate wherever possible, rather than sending it to landfill, which provides us with an additional supply of valuable resources. By 2023, we aim to reduce, and eventually eliminate, single-use plastics from our operations.

Our global waste reduction plan outlines how we’re making better use of resources through the “reduce, reuse, recycle” model. We’re aiming for true zero waste to landfill (ZWTL) wherever it’s feasible, focusing on optimizing efficiency, generating less waste, and reusing and recycling what we do generate. Currently, Ford has 102 sites with true ZWTL status.

Helping Suppliers Keep PACE

We can’t tackle environmental issues alone and our impacts don’t stop at the gate – the suppliers who make parts and components for us have their own impacts on the world around us. Our supply chain sustainability program, Partnership for A Cleaner Environment (PACE), is designed to reduce the overall environmental impact of Ford’s key supply chain partners.

The PACE program enables us to share the best examples we’ve implemented across our business with 50 strategic suppliers so that their benefits can be replicated. We encourage our Tier 1 suppliers to cascade the information through their own supply chains.

FastPACE

In addition to the full PACE program, Ford launched a new streamlined version in 2019, FastPACE, in the Asia Pacific region. With the success of participating FastPACE suppliers completing the Excel-based toolkit, which included hundreds of leading practices and actions to address air emissions, energy and water use, we plan to continue and expand the program.

Lear is committed to doing its part to achieve a sustainable future for our environment, our business and our customers. As a supplier, long-term relationships with our customers are essential, and our participation in Ford’s PACE program enables our access to best practices, driving collaboration, technology development, mutual profitability and collective improvement of the global automotive environmental footprint.”

Jack Nunes Global Vice President, Health, Safety, Environmental Management and Sustainability, Lear Corporation

Honoring Supplier Excellence

At our 21st annual World Excellence Awards, held in May 2019, 53 suppliers from around the world received accolades for outstanding performance in the fields of safety, quality, sustainability, diversity and smart technology. Five supply chain partners also received Special Recognition awards.

It’s important to us as a business that we minimize our impact on the world around us. That can only be achieved with suppliers that are willing to share that responsibility and work with us to reduce our collective environmental footprint.”

Mary Ellen Bridges Purchasing Manager, Supply Chain Sustainability

470 million gallons

Estimated water savings by PACE participants from 2019 to 2030

680,000 metric tons

Estimated CO2 savings by suppliers in the PACE program over the next five years

Moving Toward a Circular Economy

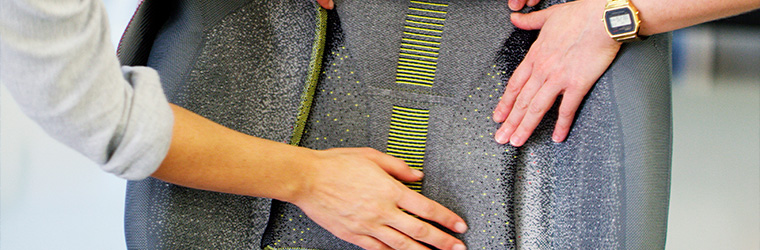

The materials in a vehicle are an important element of its overall sustainability. We aspire to use more renewable, recycled and lightweight plastic materials with lower life cycle impacts, that provide improved or equivalent quality, appearance and performance as existing materials.

Our Aspirational Goal

We aspire to only use recycled and renewable plastics in our vehicles globally.

Researching New Material Applications

We’ve been using recycled and renewable materials since the company was founded to keep waste out of landfill, reduce pressure on natural resources, and cut energy use and costs.

Recycled materials:

We’re reusing metals such as aluminum scrap from our stamping plants as well as recycling materials from outside Ford, such as post-consumer carpet and recycled tires. We continue to look at other by-products and waste streams, such as agave fiber from the tequila-making process and U.S. currency taken out of circulation, and working to integrate nylon fishing net into clips, wiring channels and brackets, reducing both weight and costs.

Renewable materials:

Our scientists have been exploring ways to use plant-based materials in place of petroleum-based plastics since the turn of the century. We were the first automotive company to launch soy-based foam in 2007, and since then, we have introduced new composites using castor oil, kenaf, wheat straw, rice hulls, coconut and tree fibers into our vehicles.

Giving Vehicles a Caffeine Boost

Through a new research partnership with McDonald’s USA, we will be using coffee chaff – the dried skin of the coffee bean – in vehicle parts. Using chaff, we’re creating a durable material for reinforcing components such as headlamp housings in the Lincoln Continental. These will be lighter, require less energy to mold and have significantly better heat resistance properties than traditional materials.

Closing the loop has been a priority for Ford for more than 20 years. We’re working with different industries to exchange materials that otherwise would be by-products or waste.”

Dr. Alper Kiziltas Technical Expert, Sustainable and Emerging Materials

New Applications in 2019

We created the first injection-molded carbon canister made from 100% post-consumer recycled carpet backing, an application that won the 2019 Society of Plastics Engineers Environmental Award.

A new material on an extension dash panel, made from recycled carpet backing and recycled tire rubber, has given a new lease of life to around 11.9 million square feet of carpet and 26,250 pounds of tire rubber.

We recently started using rice hulls to reinforce wiring channels. Their high silica content reduces mildew and fungal growth, and offers better flame retardance and lower moisture absorption than other plastics filled with natural fibers. In addition, the application offers farmers an additional revenue stream.

Sustainable materials at Ford

- 2008: Soy Foam

- Launched on Mustang

- Now on all North American vehicles

- 5 millions lbs of petroleum saved annually

- 2010: Wheat Straw

- Launched on Flex 3rd row storage bin

- Saves 20,000 lbs petroleum annually

- 2013: Kenaf

- Launched on Escape door bolster

- 25% weight reduction

- 2014: Rice Hulls

- Launched on F-150 wiring harness

- 45,000 lbs in first year

- 2014: Cellulose

- Launched on MKX armrest substrate

- 6% weight reduction

- Parts produced 20-40% faster

- 2019: Coffee Chaff

- 20% lighter

- 25% less energy

Ford Family Farm

Our commitment to sustainability and the circular economy in our in-house food service business involves minimizing waste through recycling and composting, reducing our carbon footprint and eliminating single-use plastic. We also design our menus with employee health and well-being in mind, with a focus on local, organic and sustainable suppliers, and choices that reflect local cultures and a wide range of dietary needs.

People want to know where their food is coming from, how it’s grown and that it’s safe to eat. We’re changing the way we work, providing healthier alternatives and inviting places. We are changing the employee experience while being mindful of the growing population and shrinking farmland.”

Mark Freeman Global Foodservice Strategy Manager

Sustainable Development Goals

Through our work in enhancing our world, we are contributing to the following UN SDGs: