Innovation

InnovationThe Making of a Global Vehicle: Manufacturing

A prototype of the all-new 2012 Focus tests out the assembly line in Wayne, Mich. last July. The end result looks nearly identical to this early sketch (inset)—a rare feat in the industry.

A prototype of the all-new 2012 Focus tests out the assembly line in Wayne, Mich. last July. The end result looks nearly identical to this early sketch (inset)—a rare feat in the industry.

It’s one thing to talk about a product being global but quite another to actually build something that way. Just ask the thousands of people involved in putting together the 2012 Focus, which Ford plans to manufacture in North America, Europe and Asia.

This pioneering vehicle is truly global—from the design to the manufacturing, all the way to its border-busting appeal. “We evaluated customer needs from around the globe, took the best expectations from all regions and combined them into one vehicle,” says Jim Hughes, North America Focus chief engineer. “For instance, driving dynamics is a critical element for Europeans, and we’re going to leverage that into the global Focus.”

In Germany, Ford assembled a team of its top engineers to design the vehicle; prototypes were tested on roads all over the world. When it came time to build the car, the pioneering continued. The groundwork had been laid several years earlier, when C-car Program purchasing director Uwe Pfeiffer’s global team began an entirely new approach to sourcing parts for the next-generation Focus. (C-car is an industry designation of vehicle size, and the Focus is the flagship of the new global C-car family from Ford.) Rather than ask for multiple bids, Ford “presourced”—that is, used preferred suppliers for—75% of the commodities needed for the new Focus, saving time and money for Ford and its suppliers. Says Pfeiffer, “We considered all regions in the world.”

Pfeiffer’s team decided on the best way to produce and distribute all of the vehicle’s parts, at least 80% of which are common to every Focus worldwide. “A part stamper could be a million-dollar tool,” Pfeiffer explains. “You have to ask whether it would be better to stamp those parts in one place and ship them around the world or set up another tool in another location. We’ve gone through that assessment for every part.” That was only the beginning of a global car intended to be best in class in driving performance, fuel efficiency and interior quietness. Below is a look at how and where the next-generation Focus is being built, as well as the finished product.

The Manufacturing Process

How the 2012 Focus is built, step-by-step.

| VIRTUAL BUILD Initial designs are fed into a software tool called TeamCenter, which lets engineers digitally piece together the car, component by component, to determine the build sequence. “It guides us to avoid part interferences and confirms assembly feasibility,” says Hughes, which eliminates a lot of trial and error. The resulting specifications are used to produce next-gen Focus prototypes. | |

| PROTOTYPES About 100 working vehicles are built and test-driven on demanding roads across the globe. Countless sensors collect data on vehicle dynamics, interior quietness and other parameters. “We’re trying to take the ambiguity out of the engineering,” Hughes says. After six months of continual modifications, a second prototype run of 250 vehicles is put through its paces and given final adjustments. | |

| RETOOLING THE PLANT The former Michigan Truck Plant used to produce large SUVs, such as the Expedition, with a body-on-frame process. Now known as Michigan Assembly, it was stripped down to its concrete hull and built out with all-new conveyor systems, robots and other modern equipment necessary to efficiently produce a North American Focus vehicle with unibody construction. | |

| BODY BUILD Blanks of steel are fed through one of four major press lines, where they are formed into the various shapes of the body panels. These puzzle pieces are then welded together to form the shell of the vehicle. Michigan Assembly site manager Robert Webber estimates that each Focus requires about 4,000 welds. Then the doors, hood, trunk and other closures are bolted in place. | |

| PAINT AND FINAL ASSEMBLY After the shell of the body passes through the paint building, it makes its fourth and final stop. First it goes through the trim shop, where interiors, electronics, glass, seats and the like are installed. Then it goes to the chassis area, where the engine is installed and the transmission, axles, wheels and tires are mounted. Meanwhile the plants in Europe and Asia are following the exact same build sequence. | |

| PREDELIVERY This final quality check includes visual tests, electrical tests and robots—an innovation introduced with the 2012 Focus—measuring such things as the gaps between fenders and doors. The vehicle is also fed through a severe car wash to test for leaks, and a bank of lights known as the Dog House exposes any paint imperfections. Finally, drivers take each car through a “squeak and rattle” test on a cobblestone track with tight turns. |

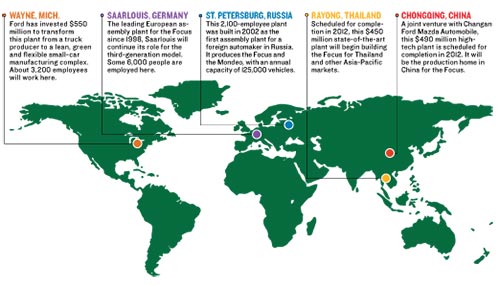

One World, One Focus

The 2012 Focus is truly a global vehicle, designed in Germany and being built in five locations.

The 2012 Focus is truly a global vehicle, designed in Germany and being built in five locations.

Connect with Ford

Ford in the Community on Facebook

Ford Community on Flickr

Ford Community on YouTube